2000 Series

Linear Actuator

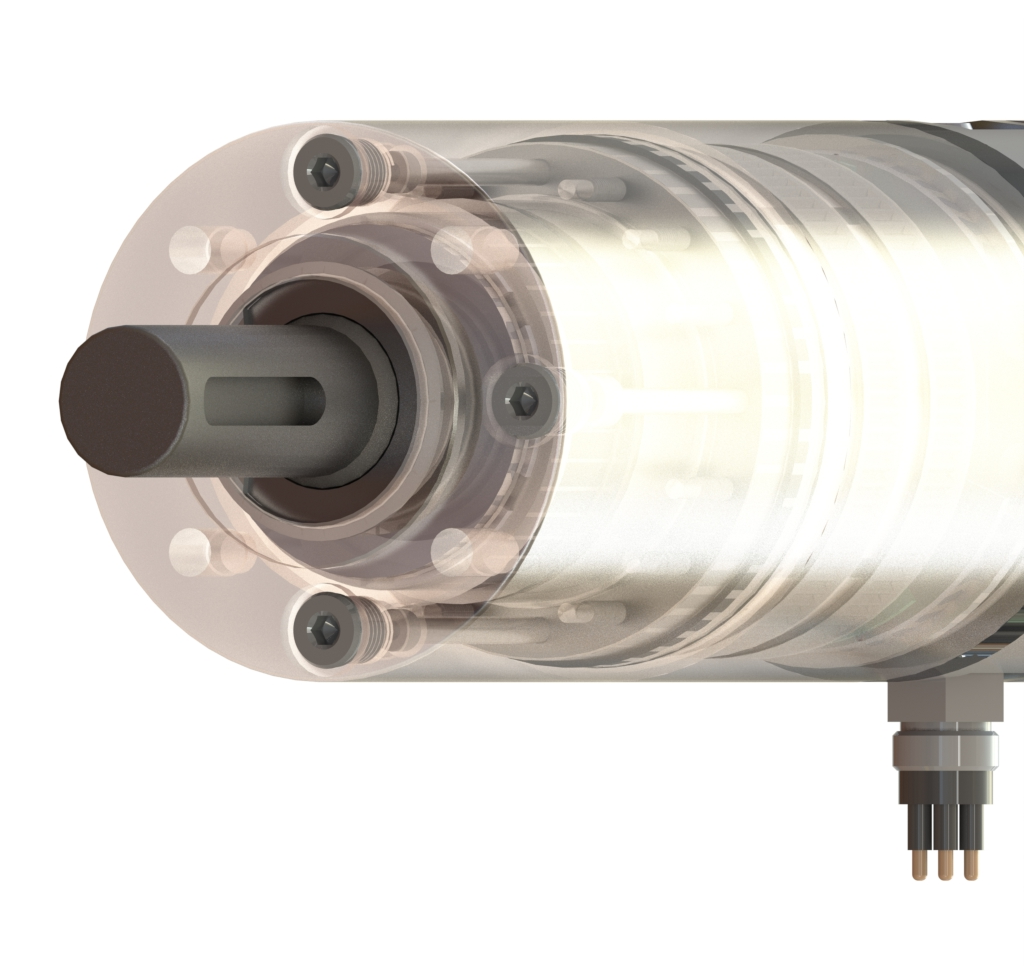

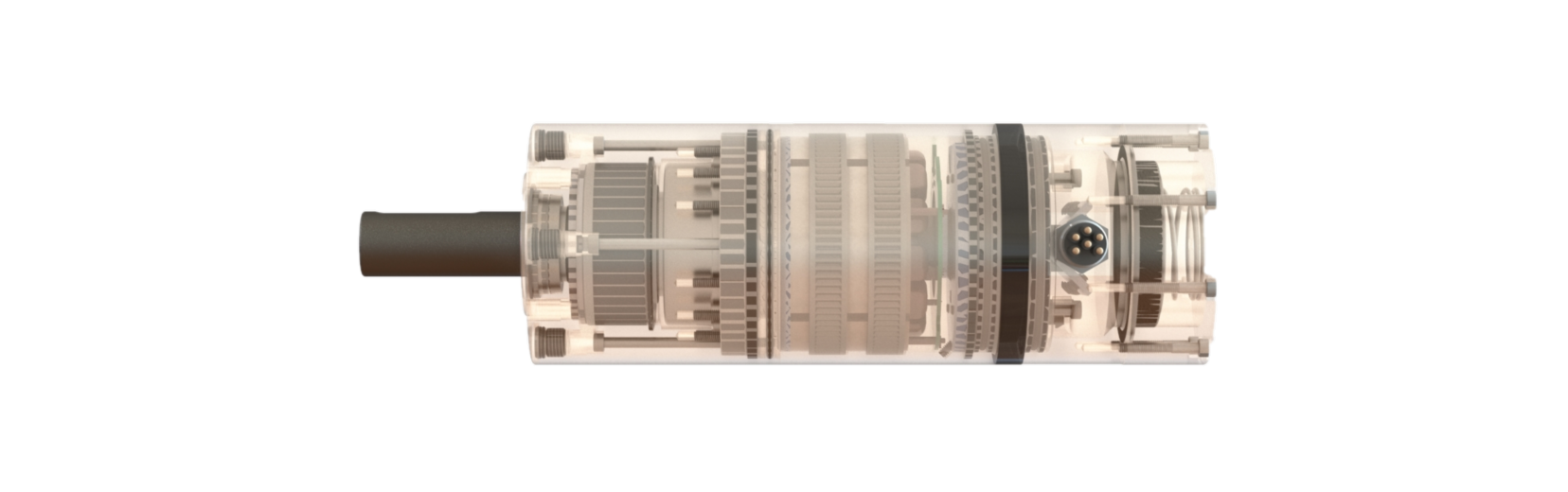

The 2000 Series of linear actuators from 2G Engineering is our smallest available size. It includes all the integrated features of our larger 3500 and 4000 Series units such as onboard motor drivers, position sensor, and servo control system.

The model features 100 pounds of output force in tension or compression, 24 V nominal operation, and serial or analog control systems as standard.

Units are 2″ in OD, have onboard compensator systems, and are rated to a depth of 10,000 ft.

The 2000 Series linear actuators have multiple configuration options to choose from:

- 2″, 4″, 6″, and 8″ stroke units are available; units above 4″ need an external compensator

- Standard operating voltage range is 10-32 V

- Unit material choices are 6061 aluminum, 316 stainless steel, and Grade 5 titanium

- Motor windings can be customized for torque vs speed preferences

- There are different options for rod ends, please contact 2G for more information

Operating Conditions

Pressure

Temperature

Humidity

Pressure rating is 10,000 psi max, which is about 22,500 ft depth in seawater.

Operating temperature range: -20° C to 65° C

Storage temperature range: -30° C to 85° C

The units can be used both above and underwater. When used above water they are considered to be IP69K rated and are suitable to be used in acid washdown environments. If your application has requirements for no hidden crevices or "traps" please contact 2G for this and other options.

Speed & Output Force

Onboard Servo Motor Drive

All 2G actuator products have integrated servo drives. These minimize the need for external systems to operate the unit. Most commonly, the units are connected to an external application host such as a PC, microcontroller or PLC system to command the units. If needed, the units can be configured to close a process control loop using an analog input, or receive an operator input in the form of a trigger signal to move to different preset positions. All 2G servo drives can be customized for user or application specific features, and have field upgradeable software.

The 3000R rotary actuator contains our 2nd generation servo controller connected to a 500 watt drive amplifier. The system features an absolute rotary encoder, accurate to 0.1 degrees with the ability to retain revolution count across power interruptions. Features of the integrated servo drive system include configurable motion profiling, velocity control, position control, gain scheduling, and cascaded servo PID control loops for position and velocity. The units come pre-tuned for stability for a majority of applications so the user does not have to adjust these parameters unless needed, while allowing flexibility for demanding applications. This makes our products easy to set up and integrate into your system.

The units use a contactless non-wearing absolute position angular encoder and do not require homing.

Precise Configuration

- Closed-loop position control with PID tuning

- Configurable limits for current, power, velocity, and acceleration

- Configurable motion profile generator

- Contactless non-wearing absolute position sensor

Communication Protocols

The following communication protocols are supported: MODBUS (ASCII, RTU, IP), 2G Packets, CAN Open, Ethernet IP. If there is a different protocol needed for your application, contact 2G and we can most likely implement it as needed.

Communication Interfaces

The following physical layer interfaces are available for controlling the units: RS-232, RS-485, CAN bus, Ethernet, Analog Voltage, and Analog 4-20ma. Additionally many units have options for redundant communication busses for having multiple hosts talk to them. Duel RS-485 is a common setup for high reliability systems.

Rugged Durable Design

2G Engineering has been building subsea motion systems since 2008. With 10's of thousands of hours of combined run time on our products subsea, we have a proven track record for use in harsh environments. The 3000 series has been designed to mate up with a standard ISO 5211 F07 mounting flange and customizable output shaft. A right-angle gearbox option is available. The units can be configured to operate from 24V DC up to 300V DC and have options for different subsea rated or industrial-specific electrical connectors.

User-Configurable Firmware

Application Software

All products include our Actuator Universal software, which can be used to set unit parameters such as current limits, power and speed. It has graphing and charting capability to help the user tune the system and measure performance. The application is available for windows, Mac, and Linux systems.

Custom Firmware

If there is a specific feature you need, please ask. All our units share common code, and if there is a specific feature, such as a communication protocol, automated operation, or state response system you need, we can implement it.

Testing & Verification

Relentlessly tested and proven under pressure

In our spacious 5500 square foot manufacturing and testing area, we are able to rigorously test our rotary and linear actuators in simulated subsea conditions, including temperatures as low as -50 C and pressures exceeding 5000 PSI.

Every product we manufacture undergoes a comprehensive Factory Acceptance Test (FAT) before leaving our facility. Our typical process includes verifying electrical and mechanical functionality, force and torque measurements, and a break-in period. A copy of the test records are included with each unit.

In addition to our standard FAT procedures, we also offer more extensive options, such as shock and vibration, environmental exposure, and endurance testing. Contact us and we will be happy to adapt our procedures to meet your requirements.

Housing Materials

Documentation & Support

Request Information

Request a quote, additional product information, or simply ask us a question, we're happy to help.